ØThe world leader of De-void Solution for process improvement and cost reduction

ØGlobal sale performance in the industries of Semiconductor, PCB, MEMS, Automobile, CMOS Image Sensor and Optoelectronic

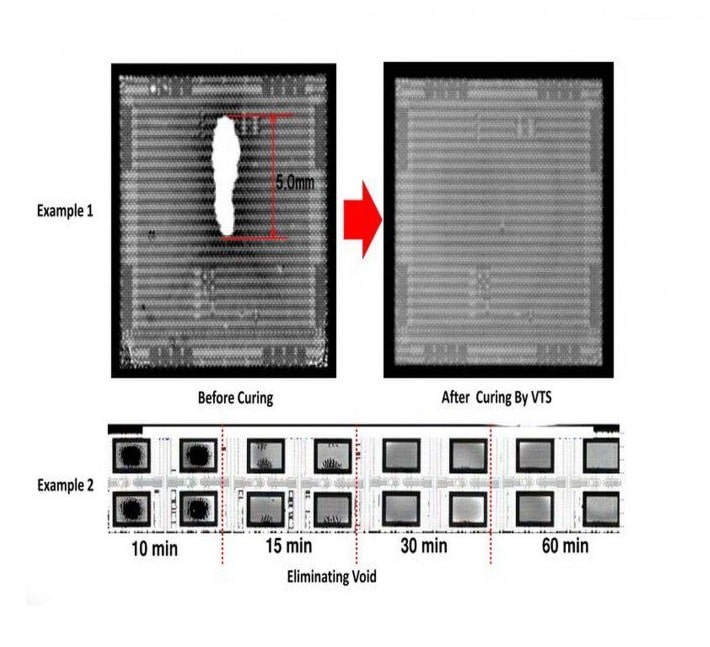

ØMass production de-void experiment of DAF, DAP, UF FOW, NCP, NCF…

| Specifications | Details |

| Power | 220V/380V 3P 50/60 Hz |

| Device Dimensions | 1,370mm(W) x 1,900mm(D) x 1,980(H) |

| Internal Dimensions | 610mm(W) x 610mm(D) x 485mm(H) |

| Weight | ~2,000 KG |

| Temperature Range | RT~200℃; Max. 200℃; 3~6℃/min @w/o Loading |

| Temperature Uniformity |

± 3℃ @ 5 ~ 8 kg/cm² 150ºC to 80ºC in ~40mins w/ Loading |

| Pressure | Max. 8 kg/cm² |

| Pressure Uniformity | ± 0.1kg/cm² |

| Operating Interface | 999 sets of hardening programs/100 steps; Temperature and pressure are programmable. |

| Control System | Separate temperature & pressure control by PLC+PC Base Touch Panel |

| Chamber Certification | Taiwan / China / USA / Japan / Korea / EU |

| Device Certification | Semi-S2 / CE / UL |

| Device Safety Design | Multiple safety sensors for pressure & temperature |

| PM & Calibration | 6 temperature detection points. |

| Modular Upgrade Design | Optional - Ensures flexibility for future upgrades, saving initial costs. |