Quick analysis for large or thick sample materials

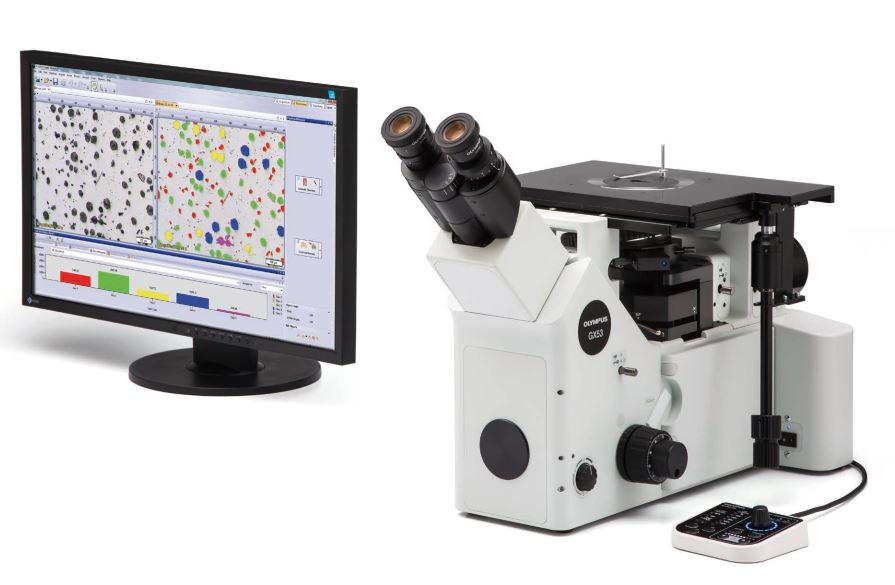

The GX53 inverted microscope is used for a wide range of applications often seen in the steel, automotive, electronics, and other manufacturing industries. The microscope enables users to inspect polished metals and cross-section samples simply by placing them upside down on the stage. The sample does not need to be leveled and can be thick, large, or heavy. The GX53 delivers crisp images that can be difficult to capture using conventional microscopy observation methods. When combined with OLYMPUS Stream image analysis software, the microscope streamlines the inspection process from observation to image analysis and reporting.

Advanced Analysis Tools

The GX53 microscope’s various observation capabilities provide clear, sharp images, so users can reliably detect defects in their samples. OLYMPUS Stream image analysis software’s new illumination techniques and image acquisition options give users more choices for evaluating their samples and documenting their findings.

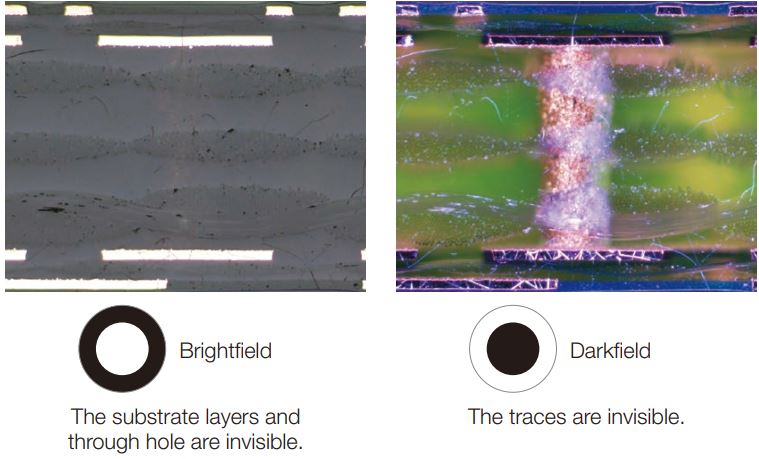

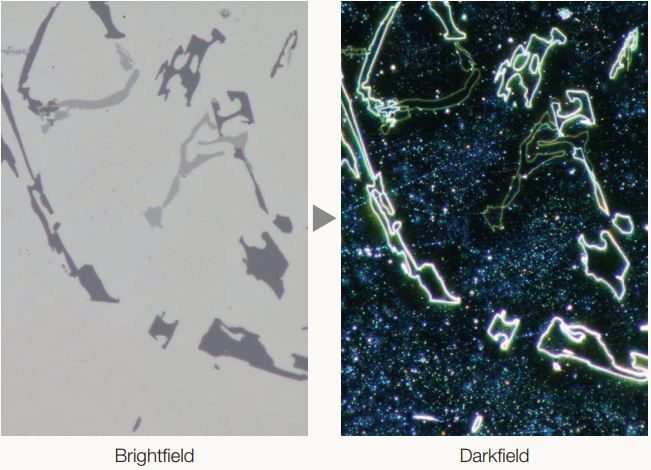

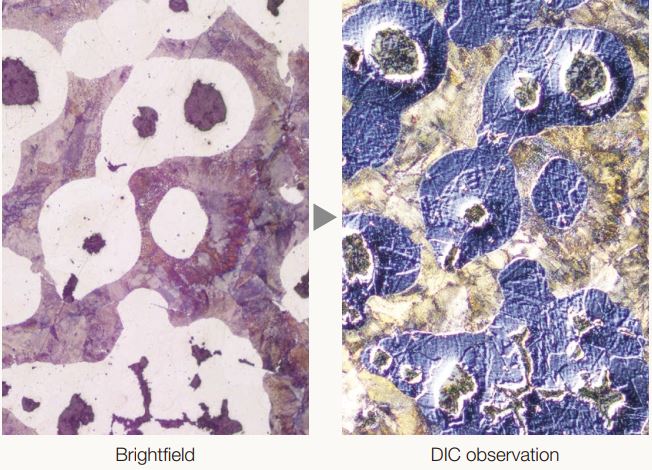

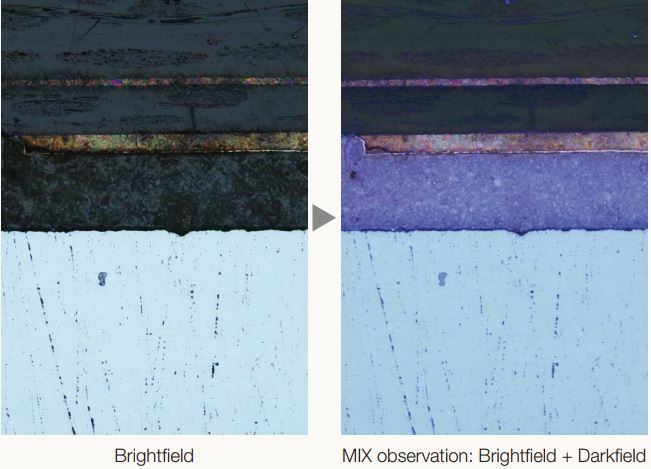

The Invisible Becomes Visible: MIX Technology

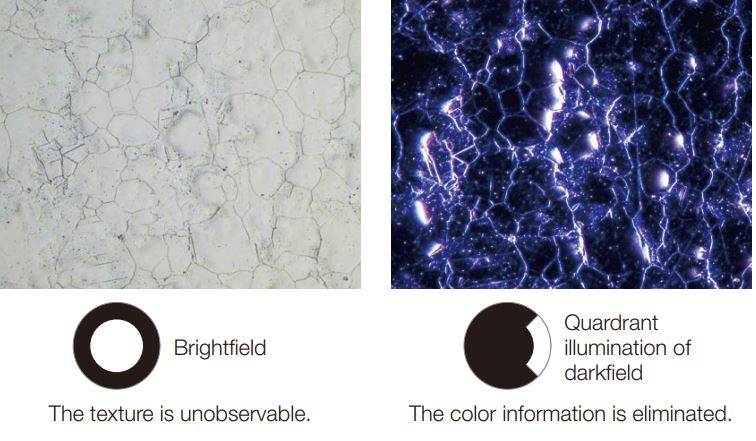

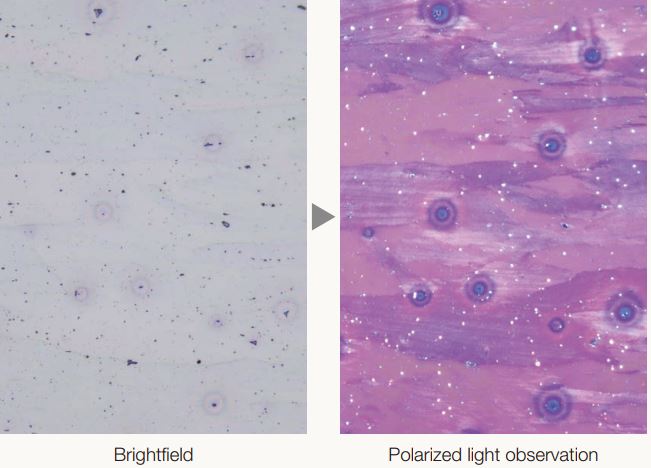

MIX technology produces unique observation images by combining darkfield with another observation method, such as brightfield or polarization. MIX observation enables users to view samples that are difficult to see with conventional microscopes, and represents even small height differences of sample surfaces. The circular LED illuminator used for darkfield observation has a directional darkfield function where one or more quadrants are illuminated at a given time. This reduces a sample’s halation and is useful for visualizing its surface texture.

Cross-section of a printed circuit board

|

Stainless steel

|

User-Friendly

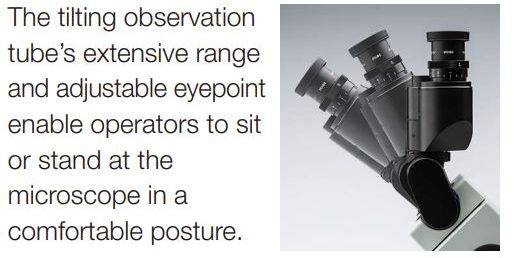

A Design That Emphasizes User Comfort

The microscope’s ergonomic design helps users stay comfortable while they work, contributing to a more efficient inspection. When used with OLYMPUS Stream software, operators can easily acquire images of diverse samples, conduct a variety of analyses, and generate professional reports.

Maintain a comfortable posture

|

Observe large, heavy samples

|

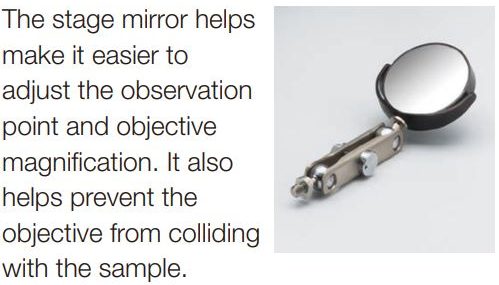

Helps prevent objective collisions

|

|

|

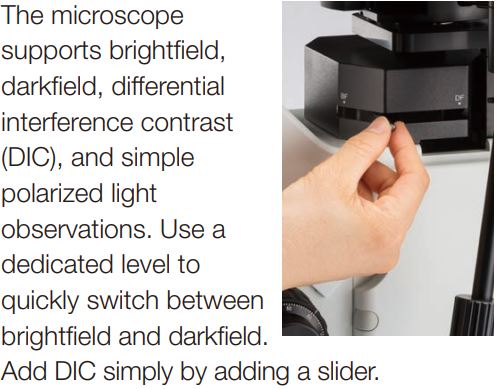

Easily switch observation methods

|

|

Instantly record observation images

|

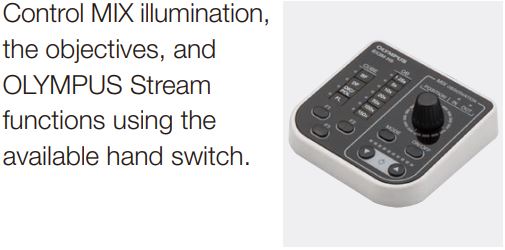

Convenient hand switch

|

Easily control the stage during observation

|

Applications

Reflected light microscopy spans a range of applications and industries. Below are just a few examples of what can be achieved using different observation methods.

Polished sample of AlSi. |

Spheroidal graphite cast iron

|

Aluminum alloy |

Electronic device |

Specifications

|

Optical system |

UIS2 optical system (infinity-corrected) |

|

|

Microscope frame |

Reflected light illumination |

Manual brightfield/darkfield selection by mirror unit |

|

Manual field stop/aperture stop switch with centering |

||

|

Light source: White LED (with Light Intensity Manager) /12 V, 100 W halogen lamp/100 W mercury lamp/light guide source |

||

|

Observation mode: brightfield, darkfield, differential interface contrast (DIC)*1, simple polarizing*1, MIX observation (4 directional darkfield)*2 |

||

|

*1 Slider for exclusive use of this observation is required. *2 MIX observation configuration is required. |

||

|

Transmitted light illumination (optional) |

Stand for transmitted light (IX2-ILL100: with field stop) is required |

|

|

PMG3-LWCD: Condenser (NA 0.6, WD 12 mm) with aperture stop |

||

|

Light source: White LED (with Light Intensity Manager) 12 V, 100 W halogen lamp |

||

|

Observation modes: brightfield, simple polarizing |

||

|

Imprinting of scale |

All ports reversed positions (up/down) from observation positions seen through the eyepiece |

|

|

Output front port (optional) |

Camera and DP system (reversed image, special camera adapter for GX) |

|

|

Output side port (optional) |

Camera, DP system (upright image) |

|

|

Electrical system |

Reflected light illumination |

|

|

Built-in LED power supply for reflected light illumination |

||

|

Continuously-variable light intensity dial |

||

|

Input rating 5 V DC, 2.5 A (AC adapter 100–240 V, AC 0.4 A, 50 Hz/60 Hz) |

||

|

Transmitted light illumination (requires the optional BX3M-PSLED power supply) |

||

|

Continuously-variable light intensity dial by voltage |

||

|

Input rating 5 V DC, 2.5 A (AC adapter 100–240 V, AC 0.4 A, 50 Hz/60 Hz) |

||

|

External interface (requires the optional BX3M-CBFM control box) |

||

|

Coded nosepiece connector × 1 |

||

|

MIX Slider (U-MIXR) connector × 1 |

||

|

Handset (BX3M-HS) connector × 1 |

||

|

Handset (U-HSEXP) connector × 1 |

||

|

RS-232C connector × 1, USB 2.0 connector × 1 |

||

|

Focus |

Rack and pinion with roller guide |

|

|

Manual, coarse and fine coaxial handle; focus stroke 9 mm (2 mm above and 7 mm below the stage surface) |

||

|

Fine handle stroke per rotation: 100 μm (min. scale: 1 μm) |

||

|

Coarse handle stroke per rotation: 7 mm |

||

|

With torque adjustment ring for coarse focusing |

||

|

With upper limit stopper for coarse focusing |

||

|

Tubes |

Widefield (FN 22) |

Inverted: binocular (U-BI90, U-BI90CT), trinocular (U-TR30H-2), tilting binocular (U-TBI90) |

|

Nosepiece |

Brightfield Holes: 4 to 7 pcs, Type: Manual/Coded, Centering: Enabled/Disabled |

|

|

Brighfield/darkfield Hole: 5 to 6 pcs, Type: Manual/Coded, Centering: Enabled/Disabled |

||

|

Stage |

Right handle stage for GX (X/Y stroke: 50 × 50 mm, max. load 5 kg) |

|

|

Flexible right handle stage, left short handle stage (each X/Y stroke: 50 × 50 mm, max. load 1 kg) |

||

|

Gliding stage (max. load 1 kg) |

||

|

A set of teardrop and long hole types |

||

|

Weight |

Approx. 25 kg (microscope frame 20 kg) |

|

|

Environment |

・Indoor use |

|

|

・Ambient temperature: 5 to 40 °C (45 to 100 °F) |

||

|

・Maximum relative humidity: 80% for temperatures up to 31 °C (88 °F) (without condensation) |

||

|

In case of over 31 °C (88 °F), the relative humidity is decreased linearly through 70% at 34 °C (93 °F), 60% at 37 °C |

||

|

(99 °F), and to 50% at 40 °C (104 °F). |

||

|

・Pollution degree: 2 (in accordance with IEC60664-1) |

||

|

・Installation/Overvoltage category: II (in accordance with IEC60664-1) |

||

|

・Supply voltage fluctuation: ±10 % |

||

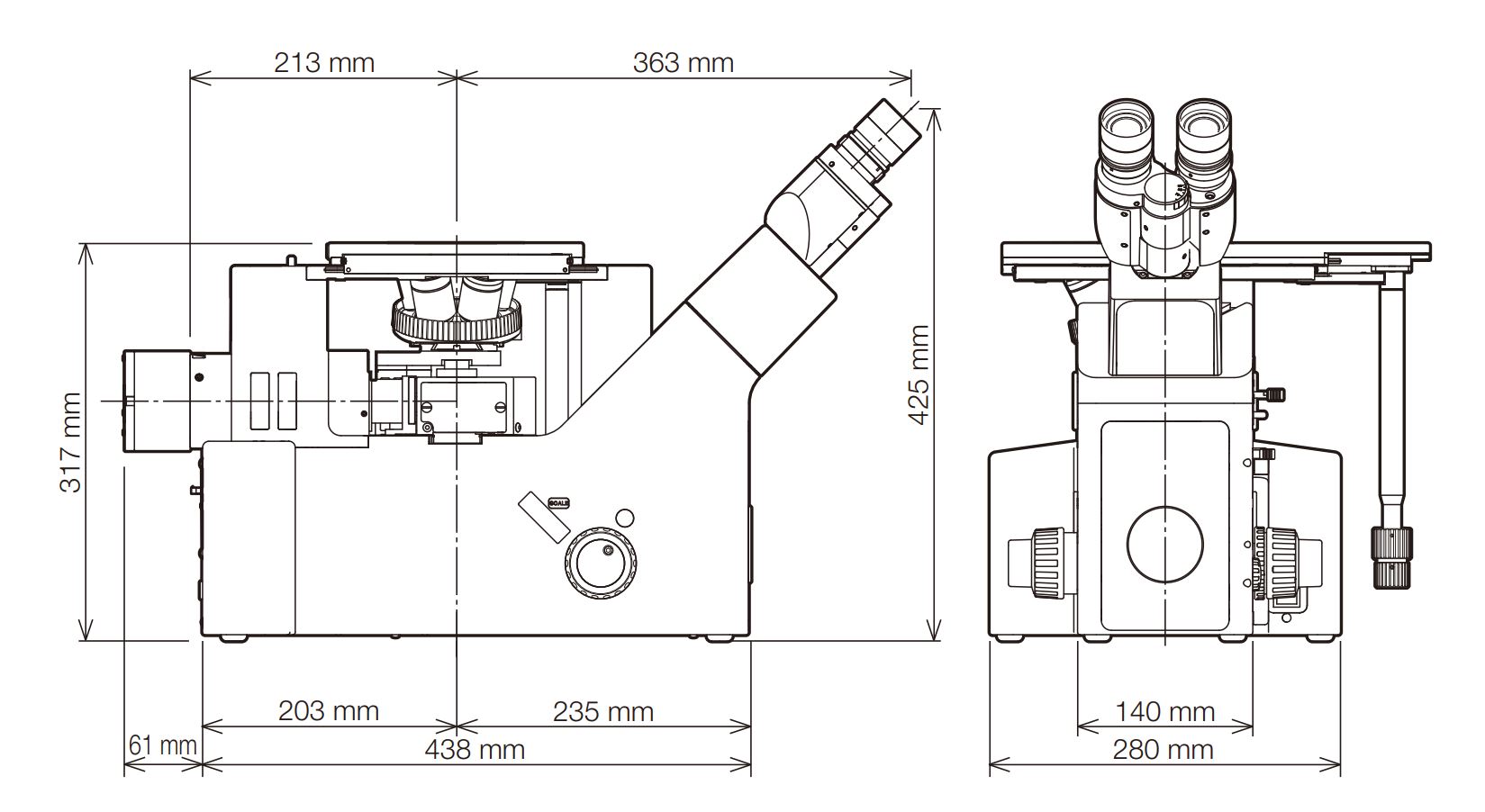

Dimensions